Winter Weather Hazards: How to Keep Construction Crews Safe

Winter, a season of festive cheer and beauty across every landscape, brings challenges and hazardous weather to industries operating in the outdoors.

One industry most affected by weather is construction.

Working in the construction industry during colder months often means battling perilous weather conditions while maintaining productivity. Ensuring safety across your crews, equipment, and job sites becomes even more crucial as icy conditions intensify hazards.

In this guide, we jump into winter weather hazards and their impact on keeping workers safe and discuss effective strategies for maintaining safety across all your construction operations.

The Risks of Winter Construction: Job Site Hazards

In order to devise an effective cold-weather safety plan, it’s essential to recognize the risks associated with winter construction.

When we’re outside, our personal thresholds for cold change often and require specific gear, equipment, and safety protocols.

A drop in temperatures could lead to frostbite or hypothermia for crew members who are ill-prepared or inadequately dressed. The same could freeze equipment and make it unusable for work. Job sites could become danger zones due to black ice and slippery floors.

Even seemingly minor conditions like dry skin from cold wind exposure can escalate to painful cracks and more serious health issues if left unchecked. Further exacerbating these concerns is the potential strain on workers’ mental health, as shorter daylight hours may contribute to seasonal affective disorder (SAD).

Here are the top construction site safety hazards in winter:

- Intense Cold and Wind Chill: Cold temperatures require workers to gear up with appropriate outerwear; workers need correct outer layers, boots, gloves, hats, etc.

- Frozen Ground: Freezing temperatures will cause ice to accumulate, leading to slippery surfaces and increasing the risk of slips and falls.

- Cold Tools & Equipment: Extremely low temperatures can make machinery operation difficult or dangerous; crews must be proactive about protecting equipment

- Snow-filled Job Sites: Snow-laden sites pose visibility issues, making excavation or other ground-level tasking arduous and hazardous

- Fewer Daylight Hours: Winter brings reduced daylight due to shorter days, leading to challenges for tasks requiring intricate detail or larger-scale surveying

- Health Risks: Cold temperatures and windchill can be abrasive; unprepared crew members are at risk of hypothermia or frostbite when exposed to the elements and must prepare accordingly

By recognizing these potential complications at the outset, you can forge a path towards ensuring smooth operations despite adverse weather conditions – thus safeguarding your most valuable resource: your construction team.

What’s next?

Investigating how the effects of winter threats at construction sites enables the creation of better preventative strategies.

8 Tips for Keeping Construction Crews Safe in Winter

Winter changes the dynamics of everyday operations on every construction project.

With plummeting temperatures, regular tasks may become more difficult to do. Workers require protective equipment and frequent breaks, slowing down work in order to keep them safe.

With these challenges, it’s crucial to keep your teams safe from potential harm.

Implement these eight strategies towards ensuring cold weather construction safety and providing your crew with a safer work environment.

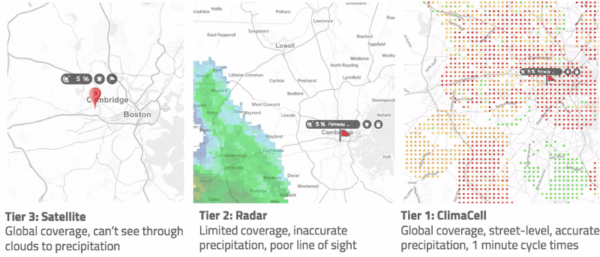

1. Monitor Weather Accordingly

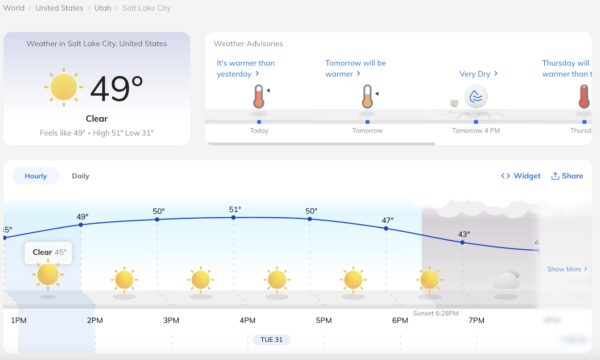

Tomorrow.io Online Weather Forecast

Understanding weather patterns and their potential impact on job sites is critical for keeping construction crews safe in winter. When working in the cold, you must be cognizant of how quickly a mild day can transform into hazardous conditions.

To start with, dedicate resources to closely monitoring local weather data. There are reliable weather apps and websites that give timely updates about changing weather conditions. They indicate if there’s a looming snowstorm or ice build-up that could jeopardize crew safety.

You should also acknowledge the implications of low temperatures for different tasks. Cold weather may severely impair machinery performance and compromise the integrity of certain materials used in construction, such as cement or mortar. Leaders must be proactive in making suitable adjustments when planning tasks.

Key Tips:

- Pay attention to daily and weekly weather forecasts.

- Tune into warnings for potential storms or extreme cold spells.

- Make necessary adjustments based on the predicted degree of severity.

- Take note of wind speeds and wind chill as they significantly intensify perceived coldness.

Our mantra must be “Safety First” when dealing with winter construction and having a goal of worker safety.

2. Educate Your Crews on Safety Protocols

A crucial step in keeping construction crews safe in winter involves comprehensive education on safety protocols and practices.

Working conditions inherently change when cold weather arrives, making reviewing this information crucial.

1. The first step is to familiarize your team with the potential dangers associated with winter construction.

Freezing temperatures, icy surfaces, and strong winds can significantly affect job safety. It’s essential to cultivate awareness about adjusting daily tasks and what changes are needed to be productive and efficient.

In order to tailor an effective learning experience, consider organizing specific training sessions that focus on cold-weather construction safety tips. For example highlight the significance of properly warming up before work begins or the best techniques to prevent slips and falls on icy platforms.

2. Hand-in-hand with providing suitable education is reinforcing protocols.

Regular briefings should become a standard aspect of your procedure — they’ll reinforce how adhering to winter safety tips for work could limit potential injury on site.

Keeping construction crews safe in winter starts by arming your teams with valuable information that they are encouraged to put into practice every day. Knowledge for everyone is key here

3. Equip Crew Members with Proper Gear

We cannot stress enough the significance of equipping your crew with adequate attire and gear when in winter. As temperatures plummet, the danger of frostbite or hypothermia lurks around every corner.

Here are our tips:

- Layers: Wearing multiple layers of clothing is better than one thick layer. This offers efficient insulation and allows them to remove layers as needed, preventing excessive sweating, which could lead to wet clothing

- Footwear: Insulated and waterproof boots ensure warmth while minimizing the risk of slipping on icy surfaces

- Gloves: Freezing temps reduces our ability to move our fingers by half! Quality thermal gloves provide necessary hand protection and keep manual dexterity intact

- Headgear: Gear that covers your entire head, including ears, is important to maintain body heat; combined with sunglasses or goggles to prevent “snow blindness” will help as well

4. Provide Necessary Winter Equipment

Along with the gear workers wear, you must also equip them with winter-specific tools and machinery to ensure safety and productivity during cold-weather construction.

Here’s a list of essential equipment and their benefits:

- Heated Machinery:

- E.g., heated concrete mixers and hydronic surface heaters.

- Enhances productivity, reduces downtime from frozen materials, and ensures quality assurance.

- Anti-corrosive Tools and Materials:

- Resists ice buildup, preserves equipment functionality, especially crucial for metal-heavy machinery or hand-held tools.

- Snow Removal Gear:

- E.g., snow blowers, mechanized snow shovels, GPS-guided snow plows.

- Allows prompt clearance of snowfall and ensures precise and quick clearance of work zones.

- Portable Heating Devices:

- Provides warmth during breaks, mitigating the effects of bitter cold winds on workers.

These tools, along with early planning and maintenance practices, significantly enhance performance and strike a balance between operational success and employee safety.

Plus, with these, you can winterize your job sites to improve safety beyond it.

5. Winterize Jobsites

Winterizing job sites involves appropriately adjusting the site and its equipment to improve safety and efficiency when operating under cold weather conditions.

In winter, construction materials may become brittle or compromised; machinery might not operate at peak performance due to freezing conditions.

Here are a few good places to start to winterize your sites:

- Heating Measures: Install temporary heating units at crucial locations around the job site. Aside from providing warm, heated breaks, these heaters prevent concrete from freezing and help paints/dyes dry properly despite the cold.

- Covering Materials: Be sure to carefully store or cover materials that could be adversely affected by frost or snowfall. Insulated blankets or tarps can protect vulnerable materials against the harshness of winter’s low temperatures.

Next is effective winter maintenance,

- Snow Removal: Promptly clear walkways, working areas, rooftops, and scaffoldings on your site post-snowfall. Accumulated snow not only obstructs movements but also adds extra weight that may cause structures to collapse.

- Ice Prevention/Lister Measures: Regular application of de-icing salts or sand creates traction on icy surfaces. This mitigates against slipping hazards, which inevitably increase during winter months.

In tandem with these efforts, consider:

- Tool Care: Cold weather brings condensation and melting, leading to rust on tools if not promptly wiped down and stored correctly after use.

Finally,

- Lighting Components: With reduced daylight hours, ensure adequate lighting is strategically placed across job sites. This way, crew members can work safely even when it’s dark.

6. Ensure the Safety of Work Equipment and Tools

Winter construction poses an increased risk not only to crew members but also to your equipment and tools. The harsh conditions can significantly compromise their effectiveness and safety, making safety more challenging. This combination could lead to equipment failures or malfunctions, posing severe risks should they occur mid-operation.

Here are two things crews can do to ensure safe equipment and tools

1. Clear Equipment and Work Areas

For optimal construction safety, a clean, clutter-free work area is a must.

A tidy workspace minimizes potential hazards and accidents related to slipping on ice or tripping over snow-covered obstacles buried out of sight. Our advice is to quickly remove accumulated snowfall throughout the day from both ground-level areas and elevated surfaces like scaffolding or machinery.

Remember:

- Regular cleaning can prevent ice build-up in critical machine parts.

- A clear workspace facilitates better navigation around construction in the winter.

- Reducing clutter simplifies identifying potential issues with infrastructure or materials due to extreme cold.

2. Mark Hidden Hazards

Enhance visibility on job sites by marking any hidden dangers. Snow and ice might hide sharp objects, deep holes, or significant changes in height that can cause serious injury if left unnoticed.

Bright markers can help mark pits or dangerous zones so workers are constantly aware of their surroundings, even during white-out conditions.

7. Align Communication Across Your Crews

As you educate your crews, remind them of protocols, and work to improve safety overall, you must ensure that appropriate communication is in place.

Communication and the ability to send out alerts and notices become vital when you’re dealing with unpredictable winter weather and the associated safety hazards.

Clear communication lines across your teams can mean the difference between a standard worksite incident and a full-blown safety crisis.

You must first establish concrete channels for prompt alerting. You can start this process by thinking through how to send out alerts.

However, pushing out information isn’t enough—it’s also necessary to ensure everyone interprets instructions correctly across crews.

Here’s how you can get it going

- Hold Regular Meetings: Before starting work each day during winter, conduct regular meetings highlighting winter work safety measures and any anticipated issues related to cold weather construction.

- Use Plain Language: Avoid jargon and use plain language in your communications so that every worker, irrespective of their expertise levels, comprehends what is required.

- Start a Feedback Mechanism: Encouraging an open dialogue where workers feel comfortable coming forward with queries or concerns gives built-in checks and balances against misconceptions or mistakes.

When it comes down to it, aligned communication is like a safety net that protects your team from preventable mishaps–and possibly saves lives, too.

8. Provide Appropriate Break Areas and Facilities

As much as outdoors work in winter is vital, it’s equally crucial to have a space for warming up and resting from harsh weather conditions. Keeping crews safe in winter involves providing appropriate break areas and facilities equipped well enough to cater to workers’ needs during chilling temperatures.

With the help of portable heaters and covered areas, you can prevent heat loss and provide workers with adequate comfort. Along with keeping them comfortable, organizations can provide drinks and snacks such as hot chocolate and protein bars to help the crew maintain the energy levels required for intense physical work under low temperatures.

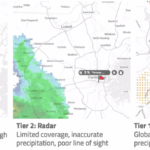

Bonus Tip: Use Weather Intelligence to Do It All

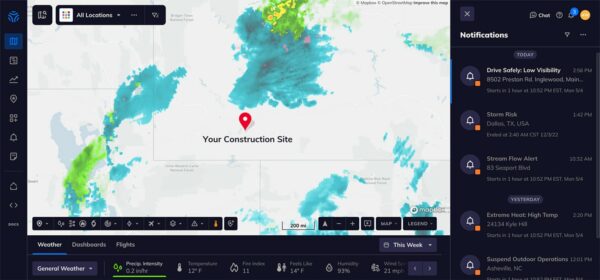

Tomorrow.io Weather Intelligence Platform

One of the most comprehensive approaches to keeping construction crews safe in winter is through the savvy use of weather intelligence systems.

Weather intelligence harnesses the power of real-time data and predictive analytics to provide detailed forecasts tailored specifically for your job sites and operations. Plus, providers like Tomorrow.io are leveraging AI and ML to improve the accuracy of forecasts and insights.

These analytics go beyond the typical weather app by offering crucial insights not only about temperature and precipitation but also wind speed, visibility conditions, windchill factor, ice formation potential, and other factors of central construction.

By leveraging these insights, you can make informed decisions directly impacting your team’s safety. For instance:

- Timely communication of sudden weather changes allows crew members to adapt their work process or secure equipment as needed.

- Prediction of adverse weather conditions can help you re-plan activities, preventing wasted time and maintaining productivity without compromising safety.

- Assessment of severe conditions like blizzards or intense frost could lead to an informed decision to halt operations temporarily.

- Knowing when windchill will reach a certain threshold improves worker safety in cold conditions

By integrating precise weather intelligence into your daily operations, you’re venturing into proactive safety management that predictively responds to challenges rather than merely reacting.

Providers like Tomorrow.io have tailor-made solutions for construction crews to not only stay safe in winter conditions but also to maintain operational safety and accurate forecasting year round.

Weather intelligence keeps your crews safe in the winter while also providing the technology necessary to adapt to weather and climate at scale.

The Future of Construction Crew Safety

As technology advances, innovation will be a true player in keeping teams safe from high-impact weather. With AI-powered predictive analysis for more accurate forecasting, keeping construction crews safe in winter becomes a bit less challenging.

One of the most exciting areas we’re innovating is weather intelligence. Data-driven insights can catalyze actions that significantly reduce workplace injuries.

Companies like Tomorrow.io are already working with construction companies, allowing them to mitigate and minimize weather impact, which aids in maintaining costs and schedules. By synthesizing all weather information, teams can automate their decision-making when it comes to keeping crews safe from winter weather.

While we welcome these innovations, we must not overlook another crucial factor in our safety equation: human understanding and adaptability.

As you educate your crews, leverage the following resources for winter work safety.

References to Helpful Resources on Winter Construction Safety

To make sure that you’re well-informed about keeping construction crews safe in winter environments, here are several key resources:

- OSHA’s Cold Stress Guide: Provides comprehensive information on identifying potential hazards and adopting measures to maintain a safe work environment.

- CDC’s Cold Stress Safety Tips: This highlights best practices during cold weather and advises coping with ‘cold stress’ situations.

- Center for Protection of Worker’s Rights: Advises you on the correct response for working in cold weather with three steps.

In our opinion, it’s worth investing time in learning this material for your crew’s well-being. Technology will continue to leap ahead in assisting us with winter work safety matters, but nothing can replace a solid understanding rooted in human insight and practical knowledge.