The $730 billion trucking industry transports roughly 72% of all goods moving through the US supply chain. Trucks deliver the food, fuel, clothing, medication, and other life essentials we depend on, so all is good so long as the trucks keep coming. But all is not well in the trucking industry.

Trucking is Inefficient

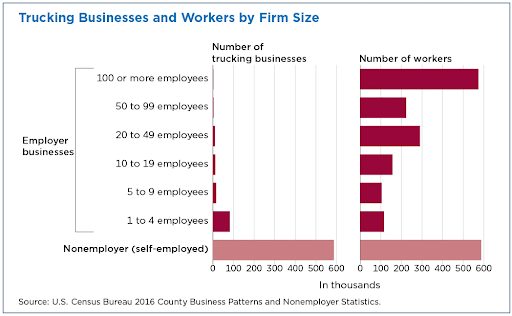

Trucking is an inefficient industry, fragmented by proprietary systems and fierce competition. The industry has nearly one million trucking firms ranging from large, sophisticated operations using robots to individuals driving a single truck with a mobile phone. This disparity has a lot to do with the industry’s poorly integrated infrastructure. Despite strides in visibility and Telematics technology offered by companies like Fourkites and Project 44, in addition to increased consolidation amongst technology providers, especially over the last year, there’s still a long way to go.

As information sharing remains spotty among carriers, especially when freight transfers from one carrier to the next and any forward visibility may still rely on legacy EDI 214. 3.3 million truck drivers, logistics providers and dispatchers still lack true visibility to risk or opportunities. The lack of collaboration, information sharing and integration is a massive barrier to visibility, resulting in tremendous inefficiencies which have long been accepted as the norm.

What Are Key Examples of Inefficiencies in Trucking?

The most frequently talked about form of waste in trucking is Empty miles, or unused capacity which refers to driving with empty trailer space. An estimated 15%-35% of all trips have empty miles. Examples of this are delivering a single pallet with a trailer that’s 80% empty or returning with an empty trailer after making a delivery.

But waste goes well beyond empty miles.

Disruptive events that include changes in weather, road work and maintenance, traffic delays, lead times and many more. Whenever conditions change, a truck must adjust its plans to meet delivery commitments. When this doesn’t happen, the original delivery plan no longer reflects the realities, requiring many resources to get back on track. The consequences of delayed shipments are expensive for the shipper, carrier, and final customers, and problems ripple through the supply chain.

Let’s dive deeper into key examples of disruption, waste and inefficiencies:

- Doubling back: A truck discards its planned route for an alternate destination due to unforeseen road conditions. For example, a driver encountering a severe thunderstorm might seek shelter or turn around when flooded roads block passage. The driver may double back to wait until the storm passes or cancel the entire mission, returning to the origin.

- Suboptimal Routing: When less efficient routes are taken, drivers spend more time in traffic and may have to quit driving for the day to comply with HOS policies. Route drivers cannot make as many pickups and deliveries, so productivity is reduced while burning more fuel and increasing emissions.

- Missed Appointments: Failure to keep a scheduled appointment means waiting for a rescheduled time or, worse, aborting the entire mission. Resolving the problem adds more time to the trip and may require a hotel stay for drivers.

- Damaged Goods: Cargo that’s prone to spoilage or damage must be monitored for temperature, humidity, and shock during transportation. Pharmaceutical, food, chemicals, plants, and other goods may result in transportation for naught without proper handling. Driving into extreme temperature, high humidity, or strong winds can mean a large freight claim and impose a hefty opportunity cost for retailers with empty shelves.

- Overly Cautious Cargo Protection Measures: Flatbed trucks haul over-sized or wide load times including building and construction materials and are tarped for almost every load to protect items susceptible to weather, even when weather isn’t an issue on the route. Tarping for every haul adds at least an hour (per load) to drivers’ time (time that may have been ideal for driving) requires specialized skills and the tarps, ,themselves, are rather costly.

- Accidents: 22% of all trucking accidents are weather-related. The total economic costs of truck accidents, including death, injury, and property damage, are $112 billion.

What Does All This Inefficiency Mean to Trucking and What Can You Do About It?

Weather is directly responsible for 23% of all these disruptions, and they cost the industry up to $3.5 billion annually. And that figure doesn’t necessarily reflect all the other related costs and challenges including higher labor costs, more fuel consumption, more miles driven, increased carbon emissions produced, higher maintenance costs from excess wear and tear, poorly utilized resources such as excess trailer space and driver time, increased pressure on operating margins and much more.

Tomorrow.io’s weather intelligence solution enables trucking and logistics companies to mitigate key disruptions and inefficiencies through proactive measures that optimize operations at scale. In our next blog post, we’ll go deeper into a key inefficiency that nobody talks about, Wasted Miles, and how weather intelligence is solving the problem you didn’t know you had.

Learn How Weather-Related Risk is Impacting Your Trucking & Logistics Business