Storm coming?

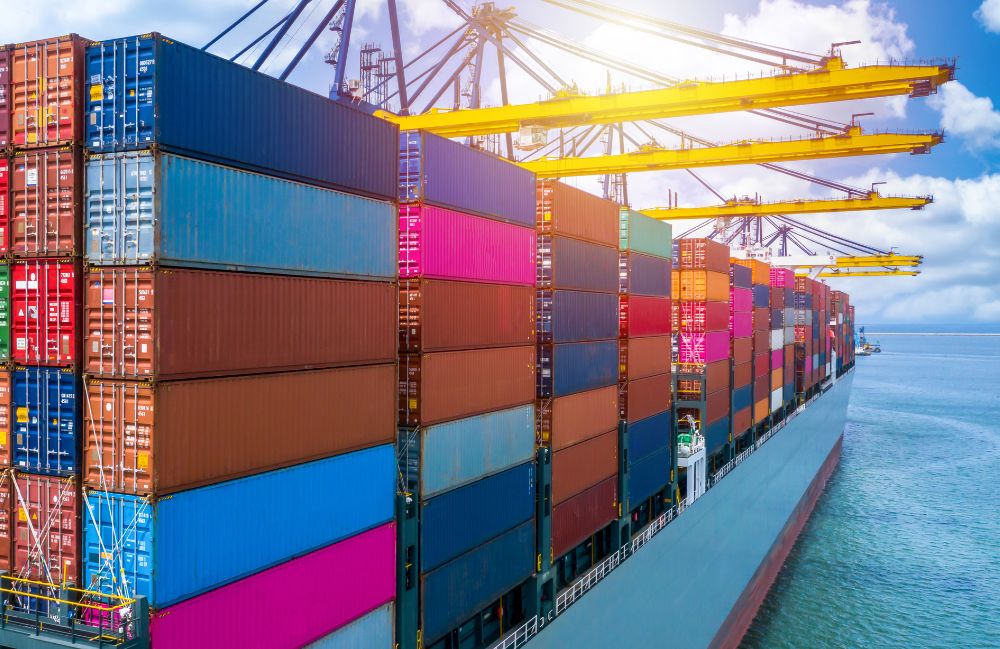

High-impact and extreme weather and shipping containers can be a bad combination.

High winds, heavy rain, freezing ice, hurricanes, and other types of weather can put the safety of your employees — and cargo — at risk.

With the largest cargo ships carrying 24,000 TEUs, the equivalent to anywhere from $29 million to $135 million in property, damaging or losing any shipping containers due to weather can cost your organization millions.

And it’s happening more often than you’d think.

The World Shipping Council collectively determined that organizations lose 568 containers a year. This doesn’t include catastrophic weather events or extreme weather but takes into account everyday bad weather that ships and ports deal with on a regular basis.

The past few years have seen a steady reduction in the number of shipping containers lost at sea. According to the WSC Containers Lost at Sea Report – 2023 Update, in 2022, 661 containers were lost at sea. The report highlights the downward trend from incidents in 2020, when ONE Opus lost more than 1,800 containers in extreme weather conditions, and in 2021, when the Maersk Essen also experienced severe weather that resulted in the loss of some 750 containers.

Poor weather isn’t just knocking shipping containers overboard; harsh weather events create delays and damages at ports, and the outlook for climate volatility brings the need for change. According to Reuters, of the world’s 3,800 ports, a third are vulnerable to the most powerful effects of climate change.

Weather impacts the entire port operations process, most significantly influencing arrival, cargo transfer, and storage.

5 Ways Severe Weather Conditions Impact Shipping Containers (and What to Do About It)

Deciding when to shut down facilities and cancel or delay shipments due to adverse weather conditions strikes a difficult balance between keeping crew and goods safe and ensuring profitability. While there are all kinds of bad weather to manage, these five types pose the greatest risk to maritime operations:

1. High Winds

Not only is it unsafe for crane operators during extreme winds, but it also increases the risk of dropping containers and damaging other cargo or equipment. A strong wind can destabilize a container when it is being lifted, and the crane operator may be unable to control it. These loads can cause severe damage if they hit equipment or structures.

Crane operations need to be suspended when wind gusts exceed 30 MPH, while the crane itself needs to be taken down if gusts are predicted to be above 40 MPH. Track winds to a specific MPH and direction in order to start, stop, or suspend crane operations.

2. Extreme Temperatures

Ships often carry perishable goods, such as meat, fish, dairy products, fruit, vegetables, and pharmaceuticals. Temperature changes can lead to increased condensation, which adds moisture that ruins the inside of the shipping container. Sensitive cargo to temperature can increase the odds of spoilage, especially in warmer weather.

Mapping temperature changes and risks allow you to prioritize which loads need to be moved first to prevent damage and delays.

3. High Waves

Choppy waters can cause items to move, fall, or break in transit. The loading and unloading process presents a particular challenge, causing ships and containers to tip over the side, or cranes to drop and damage cargo.

If this happens, the ship or port equipment will likely suffer significant collateral damage or it may even sink. With knowledge of wind advisories and detailed forecasts, coordinate loading and unloading times to minimize this risk.

4. Visibility

Fog, rain, sleet, and snow can all create visibility issues, causing a host of problems from cargo transfer to worker safety. Poor visibility can make it dangerous to operate cranes, trucks, and other vehicles. Not only can this damage cargo, but it can endanger the safety of your team.

Save thousands to tens of thousands per day by scheduling crew and shift work during ideal weather conditions to avoid waste — and keep them safer.

5. Storms and Lightning

The introduction of rain across port operations slows efficiency, causes unpredictability from wind and lightning, and can cause an unsafe working environment for workers. Lightning can be hazardous in a number of areas, but crane operation specifically needs to be managed when lightning is 10 miles away.

Snow adds another dimension, requiring you to engage with a snow removal contractor or do it yourself so that employees and truckers can arrive in the parking lot and de-ice so vehicles and personnel can work safely.

Monitor storm conditions in real-time with hyperlocal forecasting so you can predict the financial impact delays and prepare appropriately.

The Power of Weather Intelligence to Combat Shipping Container Hazards

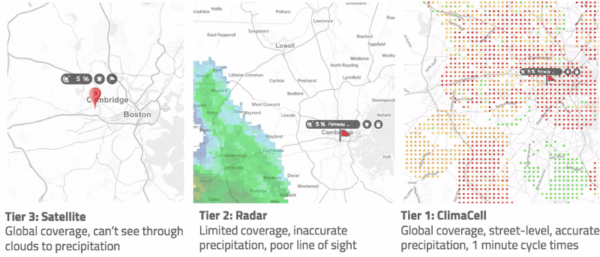

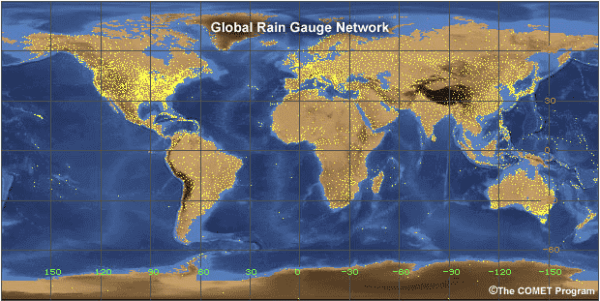

You’re probably already plugged into major weather events like storms and understand the risks for shipping and port operations. But many organizations miss the bigger picture of how climate impacts everything about their supply chain operations, whether that’s ensuring shipping container safety, staffing employees safely, mitigating collateral damage, warning employees ahead of the weather, and more.

“The intelligence that we get from Tomorrow.io, it’s literally days ahead. we can start to groom our stacks. So you think about the stacks in our facilities, they can go six to eight high and so what we then do, we take proactive steps to start to position those stacks in the event that there is a wind gust that comes through that they’re more secured..” – Bill Hamlin, COO of ITS ConGlobal

With Tomorrow.io, you can move from reactive to proactive. Predictive analytics give you the tools to understand exactly what type of weather is coming, with actionable forecasts in an easy to understand dashboard that shows you exactly how the weather impacts your operations.

Instead of scrambling to adapt to the weather, you’ll have time to prepare, automate, and adapt, all while following your specific guidelines or protocols for employees.