Imagine it’s April 30th, 2020 and you’re a port operations manager in New York City. Based on what happened the day prior, April 29th, you’re either going about your job as normal OR have to clean up one heck of a financial and physical mess. Here’s why:

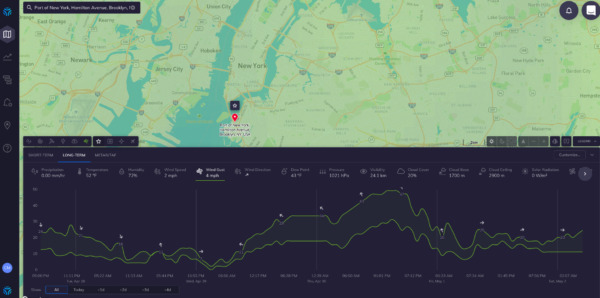

See that spike above as illustrated by the green line? That’s wind gust data for the Port of New York on April 29th. On that day, wind gusts unexpectedly spiked from the low 20 MPH to as high as 50 MPH throughout the morning and day.

Now, if you knew those wind gusts were going to hit ahead of time, then you could plan ahead and avoid any unnecessary risk or damages. If you were surprised or unprepared for those gusts, however, you would find yourself in a situation you’d rather not be.

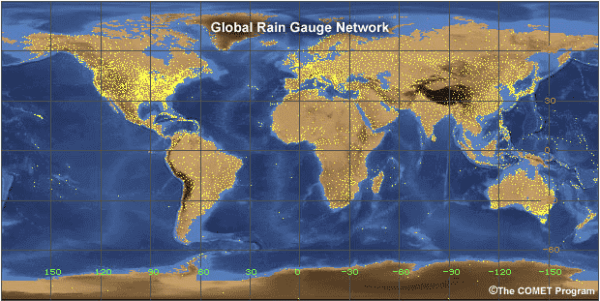

This is why predictive weather intelligence is transforming the maritime transport and port operations industry right now.

The international shipping industry runs the world. Representing roughly 90% of global trade, the International Chamber of Shipping reports more than 50,000 merchant ships across 150 nations with more than a million seafarers working crew on vessels valued at as much as $200M in building costs alone.

As if the process of navigating an ocean vessel through volatile waters isn’t enough, the real fun begins when vessels enter port and begin the unloading process. For example, simply unloading all the containers from a vessel can take up to 3 days, especially for bulk carriers or container ships with upwards of 10,000 containers. But that’s not all. The challenge isn’t just about the number of containers, as tankers carry potentially hazard oils, gas, or chemicals, and refrigerated ships carry perishable commodities that can spoil if not properly managed. Additionally, port operations managers need to coordinate things like arrival/departure, cargo transfer, onshore storage capacity, logistics, Metocean and general upcoming weather conditions.

With weather conditions being the number one cause of cargo delays costing shipping companies tens of millions of dollars each year, we wanted to take a moment to highlight the current problems facing the maritime transport and port operations industry, and present ways to take advantage of the weather to improve efficiency, reduce unnecessary cost, and maximize revenue opportunities.

Hundreds of Millions at Risk

A report compiled by IHS Markit revealed the average total cargo capacity by vessel type can be as follows:

- Bulk carrier: $97,130,857

- Container ship: $112,856,710

- General cargo ship: $29,521,611

- Tanker: $70,833,289

- Vehicle carrier: $135,778,272

Regardless of the vessel type, the value of improperly managing port operations is in the tens of millions at best, and more than $100M at worst. The main reasons why containers get damaged, while variable, are more often than not related to the weather.

Here are just a few of most commonly reported weather related container claims for example.

- Dropped container: Can happen during high winds

- Heat damage: Not managing temperatures properly

- Delayed cargo: Happens during unexpected weather at port

- Condensation inside a container: Especially if the containers are being loaded at high humidity

- Temperature changes while in-port: Increased condensation inside the container causing cargo to get wet

- Uncovered containers: During rain or extreme weather events

- Reefer containers damaged: Due to not being plugged in because of operational failure or lack of energy supply planning

Types of Weather Events Causing Damage

Weather can ruin cargo if not managed properly, which is a constant source of pain in the industry — but it doesn’t stop there. Take cranes for instance: cranes have an average cost of $2M to $35M, which makes protecting these expensive assets over time a financial priority. Weather impacts the entire port operations process, most significantly influencing arrival, cargo transfer, and storage.

- Wind: Crane operations need to be suspended when wind gusts exceed 30 MPH, while the crane itself needs to be taken down if gusts are predicted to be above 40 MPH

- Lightning: Lightning can be hazardous in a number of areas, but crane operation specifically needs to be managed when lightning is 10 miles away

- Temperature: Cargo can be at risk of damage if a sudden change in temperature impacts the insides of containers

- Rain: The introduction of rain across port operations slows efficiency, causes unpredictability from wind and lightning, and can cause an unsafe working environment for workers

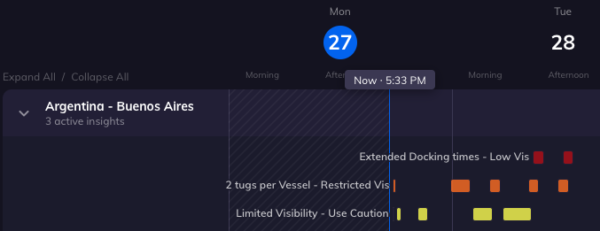

- Fog: Poor visibility can cause a host of problems from cargo transfer to worker safety

Applying Predictive Weather to Port Operations

Now that we’ve identified a few of the ways weather impacts port operations, how can you use predictive weather intelligence to your advantage?

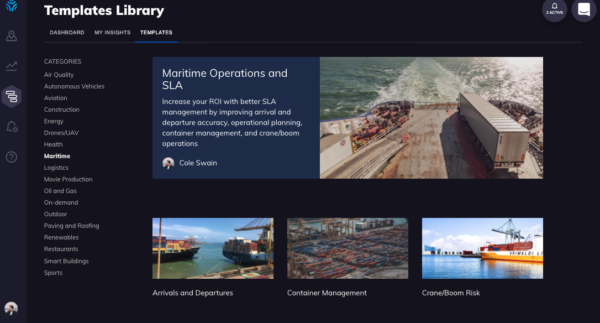

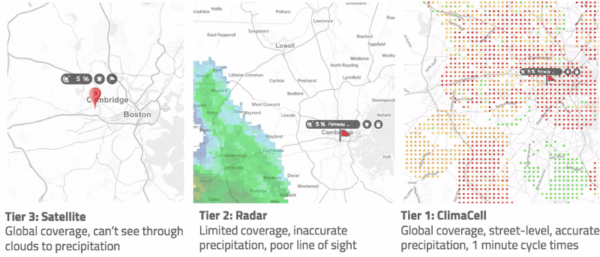

The simple way is to use the upcoming impact of weather as a way to better plan your port operations hours, if not days, in advance. In addition, getting hyperlocal alerts about unexpected weather before it hits can ensure you take the proper action needed to avoid any damages. With the right tools, you can forget about the forecast and focus on improving specific operational use cases. With pre-built operational dashboard templates or customized automated dashboards, you can manage nearly every aspect of incoming weather.

A few examples of initiatives to weather operations can improve include:

- Increase Throughput 20%: Take control of your container throughput to maximize capacity and hourly productivity

- Cost Effective Crane Operations: With cranes costing between $2M – $35M, track winds to specific MPH and direction in order to start, stop, or suspend crane operations

- Advance Operational Efficiency: Improve ROI and SLAs with efficient port operations, cargo management, and fuel usage costing $10,000 per day

- Unlock New Revenue Streams: Manage container offloading efficiency to generate an additional $1M per year

- Mitigate Financial Exposure: Expand safety measures to avoid millions in insurance premiums and employee hazard pay

- Optimize Labor Scheduling: Save thousands to tens of thousands per day by scheduling crew and shift work during ideal weather conditions to avoid waste

- Reduce Wharf and Vessel Damage: Coordinate arrivals and departures during safe weather conditions to avoid damages on vessels costing $10M – $100M+

As you can see, by harnessing the power of predictive weather intelligence you can not only get ahead of the weather, but use incoming weather to your advantage to improve efficiency, reduce costs, and maximize revenue. So the only thing you have left to ask yourself is…what’s the cost of not knowing the impact of incoming weather? What is the cost of not using Tomorrow.io?

Talk to one of our maritime and port operations experts today and find out!