2020 was an unusual and record-breaking year for many reasons, many of which had serious implications for the supply chain.

Let’s take the weather as an example. It was the most active wildfire year on record; the coldest winter since 1999; Death Valley recorded the third-highest temperature on record in August; and there were 30 named tropical storms.

But 2020 wasn’t a weather anomaly. A new report has warned that climate change will result in more extreme weather events, which will disrupt supply chain configurations with increasing more frequency.

Dr. Kevin Dooley, The Sustainability Consortium Chief Scientist and faculty at Arizona State University, explains:

“We all see the myriad of supply chain disruptions occurring during the current coronavirus pandemic. Unfortunately, this prefaces the types of challenges that supply chains will face in the future from increasing climate change. Now is the time to create more supply chain resilience.”

As the pandemic and the unpredictable weather continues to affect business operations globally, here are our predictions for how the supply chain will change in 2021 and beyond.

Supply Chain Resilience

Resilience––the word Dooley used earlier––comes up again and again when talking about the supply chain. Companies have spent years building extremely long and complex supply chains, but when faced with unprecedented events like the COVID-19 pandemic, all bets were off.

In the early days of the pandemic, there were shortages of toilet paper and other essential goods in stores as shoppers panic bought items amid fears of shortages. Nobody saw the pandemic coming, so it was always going to take some time to get back to normal stock levels.

But companies are still finding it difficult to adapt to the curveballs that the pandemic has thrown almost a year later. When France closed its border to the UK in December 2020 due to a new, highly infections variant of COVID-19, companies scrambled to work out how to get their goods into and out of both countries, and customers again reported shortages of essential items.

This uncertainty isn’t going away; companies can now expect supply chain disruptions lasting a month or longer to occur every 3.7 years.

In 2021, companies need to get a handle on supply chain risk, from factors such as the weather and climate change, financial crises, terrorism, and global events such as pandemics, so they can build resilience. The plan of action looks like this:

- Accelerating response times

- Getting better visibility into all layers of the supply chain

- Gaining a full understanding of where products and goods are at all times

- Understanding weaknesses and vulnerabilities in your network

- Building a more agile strategy

- Redesigning and simplifying products to reduce reliance on complex parts and supplies

Supply Chain Transparency

As the COVID-19 pandemic grounded flights, closed offices, and disrupted future plans, shopping locally emerged not only as desirable but also a necessity. But as consumers focused on buying locally sourced and grown products, they also became more aware of not only where products come from, but also how they are made.

Consumers are asking questions, such as:

- How much are workers in the supply chain paid?

- What are the working conditions like?

- What is the environmental and community impact of sourcing ingredients or parts?

Consumers are concerned with labor and environmental standards, and they want transparency not only from your company, but also from your suppliers and their suppliers, right back to the raw material.

This means that you need to understand and evaluate practices and processes across your full network of suppliers, so you can identify issues and bottlenecks, and be mindful of this transparency during mergers, acquisitions, and funding rounds.

Better Weather Intelligence

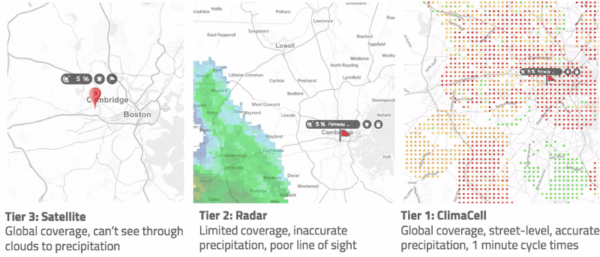

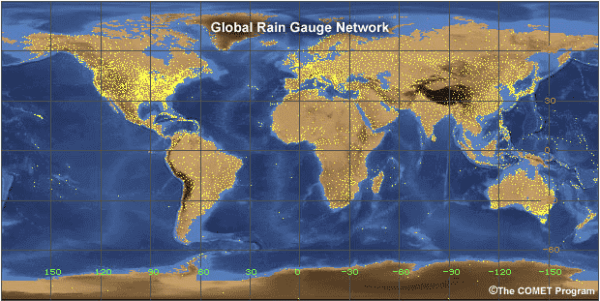

Last year’s record-breaking weather events wreaked havoc on supply chains globally. Fog, snow, floods, wildfires, droughts, and high winds all led to stoppages and delays and disrupted supply chain operations. What’s made the issue worse is the lack of accurate, up-to-date, accessible, and actionable information.

Take ocean shipping and port operations. Monitoring wind conditions is crucial in ensuring that cranes can be operated safely. However, most weather forecasts only provide general data for the area and do not include short-term severe weather events.

If you know when severe weather is going to hit in advance then you could plan ahead and avoid any unnecessary risk or damage. But your average weather forecast doesn’t pick up local weather events. Ultimately, this lack of information leads to a delay in delivering goods to customers.

Weather intelligence software can overcome these issues by predicting what’s going to happen and helping you prepare for it. It also contextualizes weather data and forecasts so you can understand weather patterns and predict the impact on your business.

Weather intelligence software provides:

- Granular insights that help you form an action plan to maximize output, reduce waste, and protect valuable assets

- Hyper-local forecasting and real-time weather, which enables you to make quick decisions to reduce delays and safely meet ETAs

- Integrated team-wide alerting that protects your crews and assets with delivery, essential support, and other services

How Does Tomorrow.io Help Manage Supply Chains?

Effectively managing supply chains means coordinating many moving parts, and synthesizing data on routes, speeds, and weather. With Tomorrow.io, you get detailed location management data to predict and prepare for whatever weather situation might come your way.

As Bill Hamlin, former COO of ITS ConGlobal and supply chain expert, explains:

“You can’t control Mother Nature. But if you have a good idea of what’s coming at you, you can communicate with your customers so you don’t waste time and money and so you can keep equipment and people safe.”

Tomorrow.io weather intelligence software helps you use data to drive business outcomes and turn insights into a competitive advantage.