Extreme weather driven by climate change is increasingly disrupting supply chains and logistics operations worldwide. Droughts, floods, storms, and temperature extremes are growing threats. To discuss building resilience against these escalating climate impacts, McKinsey, ConGlobal, and Tomorrow.io teamed up for an expert panel discussion.

John Murnane, McKinsey Sr. Partner, Warrick Nance, ConGlobal’s VP of Safety, and Mekala Krishnan, McKinsey Global Institute Partner, shared insights on leveraging data, automating workflows, and implementing proven practices to adapt operations.

Here are key takeaways from the discussion:

Conduct Location-Specific Climate Risk Assessments

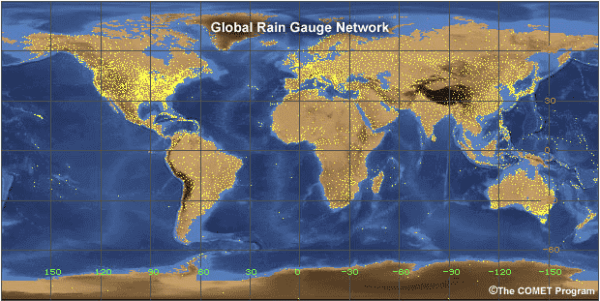

As McKinsey’s Mekala Krishnan explained, “It’s important to understand the spatial distribution of climate risks as you make decisions.” Supply chain assets and routes span the globe, with exposure varying greatly by geography. For example, coastal regions face higher flood risks while arid inland areas see more drought.

Krishnan advised building granular, location-based climate risk assessments into long-term planning. This allows tailoring resilience strategies based on vulnerability of physical infrastructure and operations. Modeling tools can quantify likelihood of climate events by site to enable data-driven decision making.

Automate Workflows Based on Weather Triggers

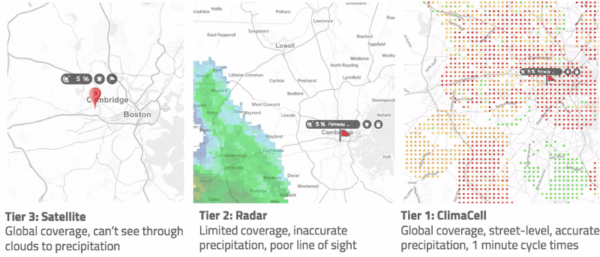

ConGlobal’s Warwick Nance shared how partnering with Tomorrow.io provides weather insights integrated into daily operations, from securing cargo stacks to winterizing equipment. Extremes like severe wind, heat, and cold can damage assets and endanger workers if not planned for.

“It puts us in a position to be able to see what’s coming and then take the appropriate actions. We’ve also adjusted some things just in managing resources. So during the winter months, when we are going to have, uh, below freezing temperatures, we can take steps that now secure the equipment in a much better way.”

Tomorrow.io’s AI assistant Gale, for example, allows teams to rapidly deploy automated response plans based on weather triggers. This prevents business disruption and mitigates safety risks. Built-in workflow automation eliminates reliance on individual awareness of weather conditions.

Blend Structural Resilience With Continuous Monitoring

According to John Murnane of McKinsey, “The modern supply chain is both structurally more resilient, but then much more closely managed.” Supply chains have traditionally optimized for cost over flexibility. Building in redundancy via suppliers, inventory, routes makes systems less brittle.

However, he cautioned this alone is insufficient – constantly monitoring emerging risks via data analytics and indicators enables adaptation. Regular “what-if” scenario exercises prep teams to respond. Murnane advised colliding supply chain leaders with experts in weather, climate, and other risk areas.

Prioritize Workforce Safety

“Resilience is really about safe operations,” said Nance. Weather directly impacts working conditions and hazard exposure. He suggested starting with workforce safety initiatives powered by specialized weather insights like excessive wind, lightning, and extreme heat alerts.

This allows for precautionary protocols to protect employees based on imminent weather-related threats. But safety must pair with operational continuity so customers aren’t impacted. Solutions like Tomorrow.io enable both safety and optimized operations through predictive intelligence.

Combine Data, Visibility, and Ingrained Flexibility

The panelists agreed that resilience requires data-driven risk analysis, supply chain visibility, and systemic flexibility. Advanced weather intelligence solutions like Tomorrow.io’s platform ingrain these capabilities.

The future of resilient supply chains is predictive, automated, and climate-aware.