It’s no secret that the global supply chain has been challenged as of late. From rising fuel prices and labor shortages to reduced production capacity and wasted miles, logistics providers face intense pressure to stand out.

Tomorrow.io’s Product Marketing Manager Brittany Viola sat down with Joe Lynch, host of the Logistics of Logistics podcast, for a ClimaCon 2022 conversation on “Building a Competitive Advantage in Trucking & Logistics.”

Here are the top takeaways from their insightful discussion:

- Too many logistics leaders still view weather-related disruptions as unavoidable: The logistics industry has historically viewed the weather’s impact as an uncontrollable cost of doing business. Now, top performers are adopting predictive systems that are allowing them to get ahead.

- Emerging technologies are becoming must-haves vs. nice-to-haves: Leading logistics providers are now pairing transportation management systems with tools like weather intelligence, visibility monitoring, and dynamic payment systems to create more scalable processes.

- Drivers trust companies who prioritize their safety: Predictive systems that allow logistics operators to warned drivers about poor road conditions not only keep drivers safer, but also increases their trust in the company. This helps organizations to combat rising turnover and boost employee retention.

Watch and read the full conversation here:

Welcome, Joe. Can you tell us about your background?

My name is Joe Lynch, and I’m with the Logistics of Logistics. I’m a podcaster, which I never thought I’d be saying ten years ago, but that’s my main gig these days. I’m from the Detroit metro area, and I grew up in automotive, which was called the biggest, baddest supply chain on Earth. I was an engineer and then a program manager, and I spent a lot of time launching cars to China and Thailand throughout the 90’s and got more into the consulting side.

Then, around about 2009, I ended up at a logistics company where everything was kind of falling apart amid the Great Recession, and I thought I’ll go to this little logistics company, and we’ll turn it around. And we did great—I was excited. It was a brand-new industry for me, although I was kind of close to it in the past, I never really was a logistics guy. I always thought I’d go back to automotive, and here we are 12 years later. I’m still in logistics and loving it. I’m excited to do what I do, which is normally podcasting on my show, but I’m excited to be here at ClimaCon 2022.

A lot of the focus in logistics right now is on improving operations, optimizing for efficiency and effectiveness. Where do you see the biggest opportunities there and where is the industry headed on that front generally?

Well, if you’re anybody who’s on an ops team, you’re always asking “How do we make things more efficient” or “How can we use fewer resources to achieve the desired result more effectively?” If you look at the trucking business, it’s a low margin business. And it’s a such a difficult business—we have already problems with driver retention, for example, and just keeping those trucks on the road. These are very expensive rigs, and we already know about infrastructure problems, along with drivers not staying in the business because it’s hard: they’re missing time with family.

So I could see ops teams saying “I would like to do a better job,” and if somebody can provide a way to ensure fewer accidents or weather-related delays, that’s enormous, right? And by the way, when you have fewer weather-related delays, not only do you have happier customers, but you also cap your drivers. I can’t imagine what it’s like to just drive a big rig. Those are enormous, right? But then it starts raining or sleeting, and you’re not so sure how long it’s going to take you to slow down. And it’s not just you driving—it’s the passenger car drivers.

So I could see a lot of operations teams and carriers saying “Yeah, this is going be better for drivers.” And by the way, if you’re a driver, I think it would mean a lot to me that the company I work for cares enough about me that they’re trying to avoid me being in an accidents or getting stuck at a rest stop, for example. So I can see this in the big, big opportunity for operations teams.

Are there ways in which you’re seeing these teams already making strides in minimizing disruptions or making operations more efficient in general?

The visibility stuff that we have going on right now—hours of service, electronic logging device (ELD), etc—have made it a lot better. Even though it’s kind of a pain and in the past, a lot of people didn’t want it, I think we’re seeing some benefits from that technology.

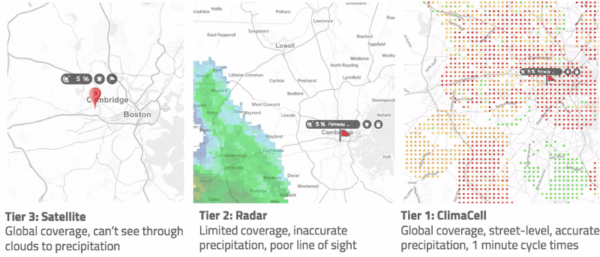

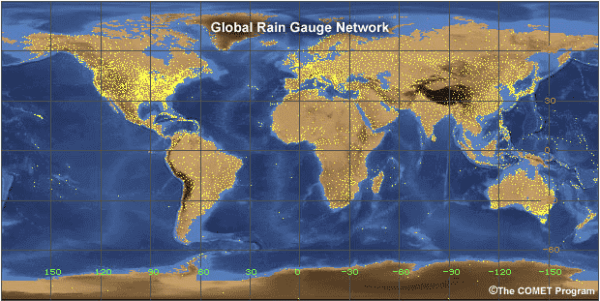

But I don’t think there is any centralized application that allows them to do anything with weathe in the way Tomorrow.io provides. II remember when I was still at a logistics company, somebody saying, “Well, we have this chemical, and it can’t go above this temperature.” But it was moving from down South to up here in the North, and we were just looking at the weather along the route and making educated guesses around what it may be at various locations. It was really just very labor intensive, and it’s not a particularly effective way to do it. So, I don’t think people are doing as much with the weather because they don’t really have a tool to deal with it. We all have consumer apps on our phones, but those aren’t a route, and for logistics and supply chain, it’s got to be a route.

Why do you think it is that weather isn’t a common conversation topic on your podcast, for example? Is it just that logistics leaders believe it’s something they have to deal with manually, and it’s just the cost of doing business?

That’s a great question. We didn’t have visibility solutions until five or seven years ago, but as soon as you see these solutions, you say “Oh, that’s what I need.” That’s kind of what’s happens in the logistics business. I think as soon as one company sees it and starts having better business results—more profit, less insurance spend, increased driver safety—then the value is apparent.

We hear about Ozone Action Days, for example, and big brands are saying “I want to be do a better job with sustainability.” 80% of greenhouse gases come from supply chains so everybody’s looking at it—and if it’s not our customers looking at it, it’s going to be the government. So I could see more companies saying, “We’d like to avoid shipping. We’d like to avoid having trucks on the road during Ozone Action Days” because that’s one of our commitments to the planet. But the challenge is how to predict that. If I’m the average logistics team, I’m just saying, “Yes, August, I think we’re gonna have Ozone Action Days,” and that’s where it ends. Finding out the day before does me no good.

Weather is hugely impactful, but what are the other types of data that you’re seeing being leveraged in the industry?

One of the things we’re seeing over time is that transportation management systems (TMS) want to do certain functions like getting your quote quickly or checking to see if truck drivers have the proper credentials to drive or if carriers have the right safety records. So we’ve connected all sorts of data sources over time to our TMS, and in recent years, we added visibility. So these manage and measure your hours of service, allowing you to make sure the drivers aren’t driving too many hours. So that visibility has grown and became more and more important.

Dynamic pricing is coming in now, too. That involves taking all sorts of inputs—maybe it’s from your own systems or external systems like Freight Waves, for example, and coming up with the perfect price, and it’s alI driven by machine learning or artificial intelligence. We’ve gotten to a place where that dynamic pricing can provide a market price and allows logistics leaders to optimize prices in realtime. So dynamic pricing is a big deal right now, and I can honestly see Tomorrow.io being a one of those apps that is going to be part of your suite of tools that you need connected to your TMS.

Could you speak a little bit more about kind of what the benefit would be for a big carrier to adopt weather intelligence, specifically, in addition to all the other things that they’re doing? And also what are the risks of not adopting this type of technology?

I think the first thing is that they want to be able to save money. This is a low-margin business, so if you can say to the operations people “we have this tool that allows us to avoid having all of our trucks on the road in bad weather” and if you’re able to over time, show fewer accidents, that’s a huge win.

The industry as a whole, along with every individual company, is trying to reduce accidents. Being able to say to your drivers “we don’t want you involved accidents, we got a truck that is well maintained and we aren’t putting you on the road in bad weather” that’s a draw. And again, getting drivers is a huge issue these days, and keeping them is a huge issue. So I see, I see some companies wanting to do that, and at some point, if you’re the one who doesn’t adopt it, you’re going to be the same one with higher insurance costs, turnover of drivers, and probably a dozen other things that are negative to your business—which ultimately makes you less competitive. That’s what it comes down to.

See How Tomorrow.io Can Help Your Logistics Team Stand Out