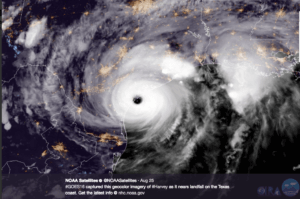

Weather in 2020 broke a number of records. There were 22 weather/climate disaster events in the United States that delivered losses exceeding $1 billion each. There were a total of 13 severe storms, seven tropical cyclones, one drought, and one (very large) wildfire that caused an additional $95 billion in damages and lost revenue.

And 2021 is also shaping up to be a record-breaking year. It’s never been more important to think about the weather in maritime and port operations.

Between global events and extreme weather, spikes in demand for maritime and port operations delayed shipments, increased congestion, and brought operational challenges that will change the industry as we know it today.

That’s why I sat down with industry leaders Duncan Kopp, Ports and Maritime Solution Lead at Jacobs, and Bob Miltenberger, CEO at NearshoreNetworks, to talk through how weather impacts maritime and port operations and how to improve ship-to-shore planning, staffing, throughput, and downtime without sacrificing safety.

It all comes down to having the right intelligence at the right time.

How Weather Impacts Maritime and Port Operations

As you know, shipping represents roughly 90% of global trade, making it a highly complex industry with tight schedules and little room for error. We’ve already seen major spikes in demand in 2020 and that will only increase — the global freight trade could grow between 330-380% by 2050.

For individual port and maritime operators, scaling will take time. Capital, construction, equipment purchases, and new technology projects have long lead times. So what can you do in the short-term to improve operations and decrease your downtime without sacrificing the safety of your staff?

Optimize your operations with weather.

“Looking at weather and projected downtimes is going to be a key focus industry-wide this year and beyond. In the U.S. and certainly on the West Coast, we’re seeing pretty severe congestion at ports and every enhancement is only going to benefit port operators, port authorities, trucking, shipping, rail, and the overall logistics community.” – Duncan Kopp, Ports & Maritime Solution Lead at Jacobs

But it’s not just bad weather that you’re contending with for maritime and port operations. It’s the everyday weather occurrences that slow things down, add downtime, or make it risky for partners, employees, and customers alike.

“It really does impact the whole logistics chain. It’s all about planning in advance and recognizing you may have some downtime due to weather,” – Duncan Kopp

Maritime and port operations have to deal with:

- High Winds. Wind speed and wind direction impact safety and downtime, since crane operations need to be suspended with winds above 30mph. Plus, high winds can put sensitive and expensive equipment at risk.

- High Waves. Wave height can make ship-to-shore transfers tricky, and cause problems for your pilots and tug operations.

- Precipitation. Whether it’s snow or rain, the type and quantity impacts visibility and safety, creating potentially hazardous conditions.

- Visibility. Fog in certain parts of the world make it challenging to operate cranes, trucks, and other vehicles, and add risk for your crew.

- Temperature. Extreme temperatures — or changes in temperature — can spoil or damage cargo, especially during heat.

It’s no secret that logistics is a competitive industry. Minimizing downtime requires scheduling efficiency, increased reliability, and predictability — made possible by weather intelligence.

1. Weather and Scheduling Efficiency

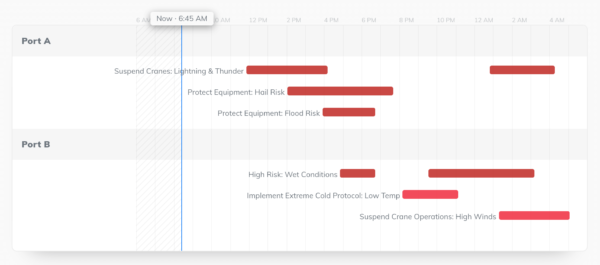

Efficiency and safety is always a balancing act. You never want to put your crew at risk, especially during tricky weather conditions. With weather intelligence, you can more easily predict exactly when bad weather will strike, and schedule your shifts around it.

“Keeping our folks safe at sea and onshore is paramount. And it’s the number one impact to our finances, our success, and our productivity. The ability to schedule staff at the right times makes a huge impact on our efficiency, just eliminating the human expense of our teams waiting for something to happen when there’s a delay due to weather.” – Bob Miltenberger, CEO at NearshoreNetworks

Understanding the complete picture of what weather will impact your operations means you can schedule ground crew, pilot boats, and ship-to-shore transfers based on what conditions occur in real-time.

2. Increased Reliability

It’s not just staffing that matters when it comes to everyday weather events. With ships containing anywhere from $29 million to $135 million in property, damaging or losing any shipping containers due to weather costs your organization millions. And that doesn’t even include the cost of equipment damage — vessels, cranes, rigging, winches, containers, and more can easily add up to millions in damage that can easily be avoided with weather intelligence.

“The environment and weather plays a very important role in what we do. Your hardware includes everything from the vessel level all the way to shore, and all of that has to be working for you. And it’s not just the long-term impact of a predictable storm that’s coming in within a cone of expectancy, but the afternoon thundershowers that create a lightning path, or other short-term, unexpected events. What may start up as a gentle squall can quickly escalate because conditions coalesce and suddenly you drop below standards of operations.” – Bob Miltenberger, CEO at NearshoreNetworks

With those concerns in mind, simply looking at a weather forecast isn’t enough. You need to be constantly evaluating the weather according to safety guidelines and best practices for operations.

3. Easy Weather Predictability

Port and maritime operations have many moving parts that all can be impacted by different weather systems at the same time. You have to manage:

- Cross-ocean shipping lanes and carriers

- Near-shore operations with tug and pilot community

- Ship-to-shore crane operators

- Terminal, container yard, and railyard operations

- Intermodal gates, trucking, and warehousing

Rather than reacting to whatever weather gets thrown your way, use weather intelligence to predict conditions when and where they’ll happen, giving you the ability to quickly change what staffing and equipment you need ahead of weather events.

“The ability to predict weather events and have your hardware ready to go, whether it’s the vessel moving in a different direction or buttoning everything down with an understanding of when the conditions may correct, it really has a positive impact. The reduction in equipment being damaged, the safety of our personnel, it all comes together with Tomorrow.io.” – Bob Miltenberger, CEO at NearshoreNetworks

With Tomorrow.io’s predictive analytics, you can give several days’ advance notice on what to expect and schedule staff around any weather events, rather than having to react in the moment.

Efficiency, Reliability, and Predictability with Tomorrow.io

The port is an increasingly dynamic environment. With a weather intelligence platform like Tomorrow.io, you can access one source of truth around the weather conditions that impact every area of your operations.

“There are competitive advantages in knowing the weather on a localized basis. It’s extremely important to the vessels approaching the port, extremely important to vessels in port, and extremely important to tenants and participants of loading and unloading activities, whether it’s passengers or cargo. When a potential new client is looking at places to berth, I believe weather intelligence is an asset to your total value solution.” – Bob Miltenberger, CEO at NearshoreNetworks

With Tomorrow.io, you’re able to:

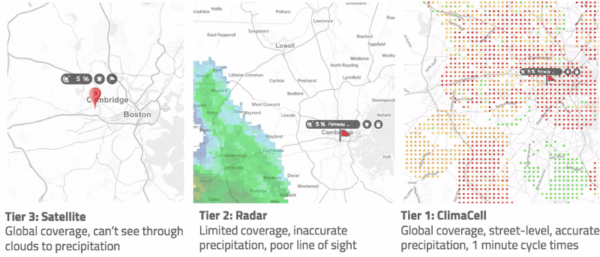

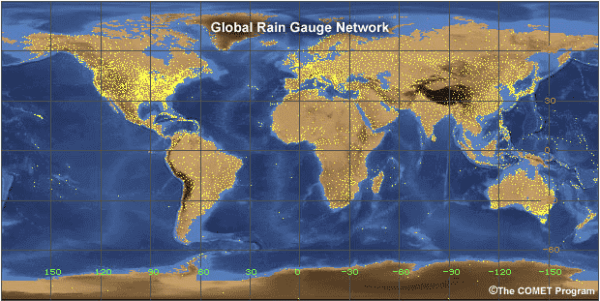

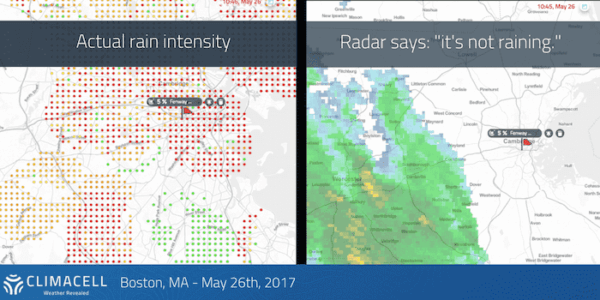

- Focus on what matters. Drill down to a 500m by 500m resolution so you know exactly what’s going on and what’s going to impact your operations several days in advance to keep your team safe and efficient.

- Update your operations in real-time. Tomorrow.io gives you minute-by-minute updates so you can understand the weather impact on your business, whether that’s crane operations, cargo management, or seasonal changes.

- Proactively take action. With a predictive outlook, you don’t have to react to weather events. Know what’s going to happen in advance and adjust your operations ahead of time, incorporating it into your situational response plans and customer communications.

You probably already check the weather forecast each day or at the start of each shift. But at Tomorrow.io, we think about weather intelligence as more than just the forecast. Knowing there will be high winds on Tuesday in Washington is helpful, but not detailed enough to make operational changes. When will the winds start? Will they be 50mph or 15mph? What direction will the winds blow? Does that mean I have to stop crane operations?

With Tomorrow.io, you can answer those questions and more. We’re not going to tell you the forecast — we’ll tell you what to do about it. Tomorrow.io shows when to cease crane operations from what hours, what survey codes need to be updated, and how to staff appropriately so you’re not caught surprised by any weather that comes your way.